Wichita Clutch HBS Brake for River Current Turbine

A marine renewable energy technology company, needed a heavy-duty brake for the latest version of its river power generation system. When submerged, the river’s current flow turns multiple crossflow turbines which drive a single generator. The resulting emission-free electricity is transported via cable, directly into existing remote community grids.

River Power Generation System

The river power generation system is specifically designed for reliable operation in remote and rural regions where communities have no access to traditional energy infrastructure. The system’s low vertical profile allows for deployment in shallower rivers with no visible surface features. A towable pontoon support structure features a ‘self-deploying/self-retrieving’ remotely-activated buoyancy system.

The OEM contacted Wichita Clutch for a fully-submerged, robust, dynamic braking and holding solution that would prevent undesirable, potentially damaging rotation of the turbines when the system is shut down in an emergency or when parked during periods when river flow and weather conditions prohibit operation.

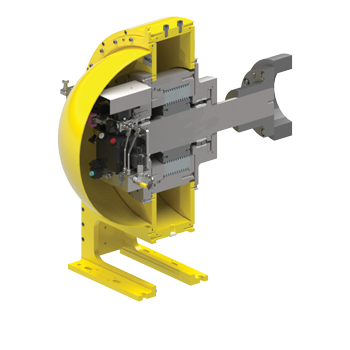

Wichita HBS Brake

A spring-set, oil-immersed HBS brake in a fully enclosed water tight supporting structure was selected for this challenging renewable energy application. The multiplate ‘wet brake’ solution provides a stopping and holding torque capacity of 27,000 Nm and dissipates the stopping energy by transfer into a store of cooling oil contained within the wet sump of the structure. To meet customer ‘plug and play’ requirements, Wichita engineers also developed an integrated HPU and control module that was close coupled to the brake structure and protected by use of a hinged metal spun, stainless steel dome cover with a dual O-ring sealing system.

Download a PDF of this article

- Spring-set, hydraulic released, oil-immersed brake with integrated foot mounted support structure and integral bearing supported shaft for easy customer connection via a shaft coupling

- Fully enclosed design suitable for river submersion up to 30 meter depths

- 27,000 Nm of stopping torque

- Integrated electro hydraulic power unit with MODBUS TCP control, featuring internal and external monitoring and braking profile control

- Variable stopping torque profiles can be achieved by adjustment of the hydraulic controlling pressure decay