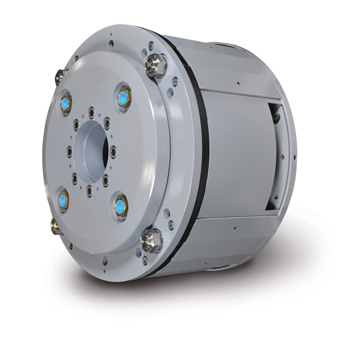

Wichita Clutch AquaMakks LI-SSB Brake for Diving Support Vessels

Wichita Clutch has supplied AquaMaKKs low-inertia, spring-set brakes (LI-SSB) for use on diving support vessel (DSV) mooring winches. The DSV is used for inspection, maintenance and repair of offshore oil and gas pipelines and platforms. A 4-point, computer-controlled mooring system maintains the ships position over a dive site while compensating for swell, tide and prevailing wind.

AquaMaKKs LI-SSB brakes are installed on each of the mooring system’s four deck-mounted, AC motor driven winches. The units serve as stop-and-set parking brakes to hold the vessel in precise position. In the event of power loss, the brakes are calibrated to provide a controlled emergency stop which prevents vessel drift while protecting drivetrain components.

The AquaMaKKs LI-SSB has been specially modified to withstand highly corrosive sea spray and direct seawater splash prevalent in marine deck areas. These LI-SSB models utilize the standard, offshore-proven, AquaMaKKs brake housing which features three-part epoxy marine grade paint and stainless steel hardware for added corrosion protection. Special alloy stainless steel wear (center) plates are also incorporated to resist damage from corrosion. An engineered friction material was specially designed to run against the stainless steel wear plates.

AquaMaKKs LI-SSB air-cooled, air tube release high-torque brakes are available in the 19, 25, and 36 inch sizes. Units feature a shim design that makes it easy to maintain and adjust for wear. Models can be easily converted into water-cooled brakes.

Download a PDF of this article

- Low inertia, air-cooled, spring-set, air tube release, high-torque brakes

- Specially modified to withstand sea spray and direct seawater splash

- Provides accurate torque control

- Three sizes available with up to 750,000 lbs. static torque rating