Wichita Clutch LI-SSB Brakes for Limestone Quarry Conveyors

A leading mine conveyor OEM needed heavy-duty brakes for use on a group of conveyor packages at a cement plant in Columbia, South America. The series of three conveyors transport limestone within the facility’s quarry and processing areas.

To meet the individual conveyor application requirements, Wichita Clutch provided three sizes of its popular low-inertia, spring-set brakes (LI-SSBs):

- Model 130H with a 260,500 in.lb. (29,432 Nm) torque rating for a 185 m long conveyor

- Model 330H with a 589,900 in.lb. (66,648 Nm) torque rating for a 148 m long conveyor

- Model 236H with a 760,000 in.lb. (85,866 Nm) torque rating for a 263 m long conveyor

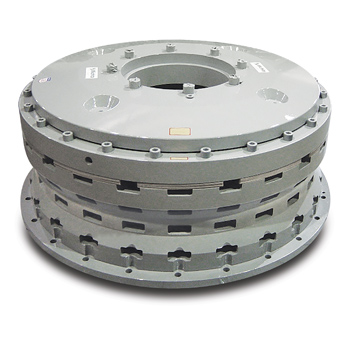

The Wichita Clutch LI-SSB spring-applied/air-released brakes feature low-inertia stop/start parts that reduce deceleration times and allow more cycles per minute. They also reduce the heat generated during dynamic braking conditions.

Models feature full-circle friction discs and are available in 1,2,3 or 4 plate designs. Three spring ratings are offered to suit individual application requirements for torque, heat, response and space. LI-SSB units are designed for end-shaft or through-shaft mounting.

Download a PDF of this article

- Low-inertia, spring-set, air tube released brakes

- Air tube design provides fast response with smooth engagement

- Reduced deceleration times

- Reduced power consumption and heat build up

-

Phone

- 940-723-3400

-

Fax

- 940-723-3436

-

Website

- CONTACT